Two Loop FIBCs

Two loop FIBCs are usually less complicated and the most cost effective form of packaging. These bags are different in construction compared to that of the other special bags. The two lifting loops are formed by the body of the fabric itself which gives an advantage of high tensile strength and easy lifting operations.

Two loop bags are mostly used if wider opening is needed for filling the bag. The loops are tied together for lifting as a single loop.

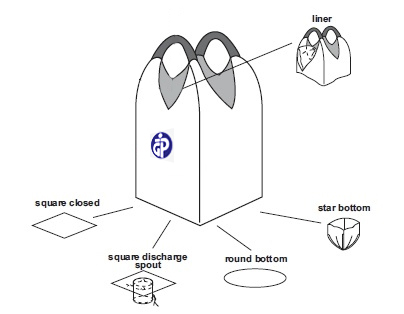

The designs consist of an outer bag with either a single or double integral lifting loop configuration. Coated or uncoated operations are available depending on customers requirements. Inner liners shall be inserted to give additional moisture protection depending on the product and application.

- Coated or Uncoated fabric

- Safety factor of either 5:1 (single trip) or 6:1 (multi trip)

- Multi color prints and supplied with a variety of document pouches and labels

- Conforms to the most stringent international standards

- Standard open top with filling slit

- Filling spout with sewn-in lid

- Square or rectangular sewn-in base

- Star base

- Gusseted and sewn base

- Discharge spout (standard or Iris closure)

Type A bags are made from standard polypropylene material which is a non-treated insulating fabric.They have no special electrostatic safety features. These bags are cost effective and ideal solution for materials which are not hazardous, food or pharma related.

Type B bags are very similar to the Type A bags as they are made from the standard polypropylene material, they too do not have the ability to dissipate static electricity efficiently. The difference is that the material used is an insulating fabric but this has a low breakdown voltage (less than 4KV) to prevent propagating brush discharges (PBD) which are highly energetic and dangerous. Type B bags can prevent PBD, however normal brush charges can still occur so these bags cannot be considered to be anti static in any way. Type B bags may be used in the presence of the combustible dusts with MIE of greater than 3mj but in the absence of flammable vapors of gases.

Type C bags known within the industry as conductive or groundable Bulk Bags or conductive FIBCs. Constructed from non conductive polypropylene material interwoven with conductive yarns that form a grid pattern, these are designed to control electrostatic charges by grounding. The bag MUST be electrically grounded during filling and emptying – this is essential to the safe use and performance of a Type C bag.

Food grade bags are bags that are made with the intent of putting food products into the bags. A Bulk Bag that is manufactured in a facility that has undergone an audit and is certified by a food safety standard.